We want to create valuable, timeless hats by working with a creative mix of tradition and innovation. For each Lou-i we face the challenge putting things together that belong together. Finding the right combination of selected wood, finest fabric and genuine leather closure is like putting puzzle pieces together. We make sure that all fits together perfectly before a Lou-i goes to production.

The wood for the visors is chosen according to color, durability, fine grain, value and to strict and responsible criteria. This is followed by 15 work steps which will remain secret. There is one thing we can disclose – these custom manufacturing methods make our visor malleable, so you can shape it the way you want it.

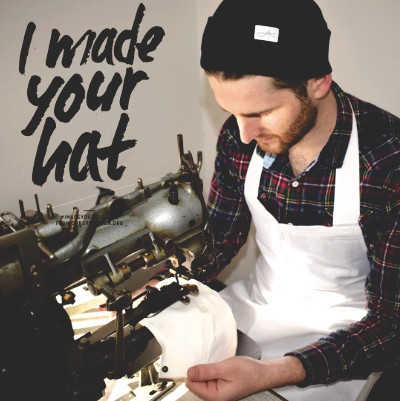

After producing the real wood brim we can get down to create the crowns. We start to process the fabric. With the help of stencils, the panels are manually cut. We move ahead with ironing the panels and in particular ironing the interlining for the front panel. When we are finished, we are ready to sew the crown together – 11 sewing steps are necessary and that requires superb craftsmanship.

The core of our work is to assemble the visor with the crown and then with the sweatband. By using a special sewing technique we create the soft and smooth liners, which promise incomparable wearability of our hats.

The last steps that were taken in the course of this handcrafted process led up to sew on wooden button and labels. And at the very end we check the quality of each Lou-i and wrap the unique Caps with shining eyes.

A unique Cap with wooden brim is born. Made in Germany. By humans. With love.